Home | SEA WATER DESALINATION PLANT | Containarized SWRO Plant

SEA WATER DESALINATION PLANT

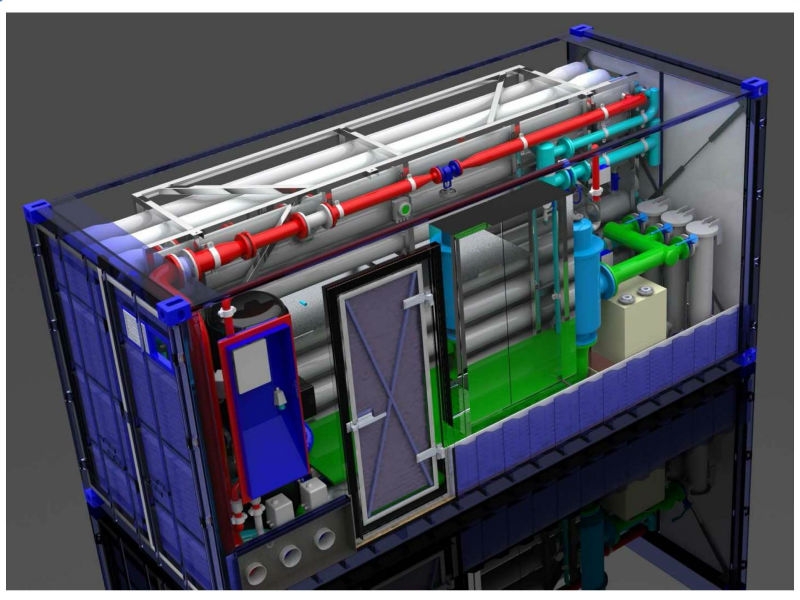

Containarized SWRO Plant

System Description

The proposed system is comprised of one (1) train of modularized and containerized desalination units based on various stages of treatment by:

1. UF Membrane System (Ultra Filtration),

2. SWRO Membrane System (Sea Water Reverse Osmosis), and

3. BWRO Membrane System (Brackish Water, or second pass, Reverse Osmosis).

The membrane system is capable of producing 3,000 m3/day or 3 MLD of desalinated water when operational. The modularized concept design enables each system to operate and undergo cleaning-in-place (CIP) independently. The advantages include rapid on-site installation and commissioning of the system; including

the flexibility of allowing each train (if multiple trains are installed) to be decommissioned, relocated and transported to other sites when required.

All high pressure piping shall be constructed of Super Duplex Stainless Steel (SDSS) or equivalent which can withstand the corrosive seawater conditions in KSA.

UPVC, PE or FRP or SS316 stainless steel will be used for the lower pressure or treated water applications.

Design Conditions:

1) Seawater design qualities for SWRO Plant

2) Treated Water Qualities

•Product Water Capacity : 3,000 m3/day or 3 MLD

•Product Water TDS( 2nd Pass RO) : < 100 ppm @ 25 deg C

• TDS : < 43,000 (25 °C) mg/L

• pH : 7 to 8.5

• Turbidity : < 20 NTU

• Temperature (maximum) : 35 °C

• Temperature (minimum) : 25 °C

• Oil, grease, heavy metals, oxidisable matter, COD, BOD : NIL

• TOC : <10 ppm

• COD : <30 ppm

• TSS : <10 ppm

• Silica : <10 ppm

• Boron : <5 ppm

Plant Dimension:

The 3 MLD (125 m3/hr) desalination system requires 11 nos. x 40” containers to be installed. Window mounted air-conditioned containers will be provided.

UF Membrane System

Pre-filtered seawater is pumped using variable speed controlled pumps from the existing intake structure to the UF containers. Each UF train consists of VFD controlled feed pump, automatic strainer with 130 micron rating, valves and instruments, and 288 nos. of Kristal® UF modules, which are housed in three (3) nos. of 40 ft

containers The UF train is fully automatic and each train runs independently in producing filtrate water. With the dedicated CIP and backwash

arrangement, one UF train can undergo CIP while the system still produces the design capacity output. Another two (2) nos. of 40 ft containers will house the ancillary

equipment like CIP and pumping systems.

SWRO Membrane System

The UF filtered water is fed into SWRO membranes using two pumps operated in series a turbocharger-type Energy Recovery Device (ERD) in each train. The first pump is a VFD operated low pressure booster pump, which feeds water into the high pressure (HP) pump. The HP pump further increases the water pressure and feeds the water through the ERD to reach the final pressure required for SWRO. The ERD transfers energy from the RO brine concentrate to the incoming feed water, reducing the energy required to perform the RO process.Each SWRO train consists of dedicated feed pump (VFD operated), HP pump, startup control valve, ERD, RO pressure vessels, RO modules, and necessary valves and instruments. Each train is equipped with 38 nos. of pressure vessels, each containing 7 nos. of RO elements, having a total of 266 nos. of RO modules per train. The control valve is installed after the discharge from HP pump for pressure control to ensure smooth startup of the SWRO system.

The SWRO train operation is fully automatic and each train runs independently to produce desalinated water. With the dedicated CIP arrangement, the train can undergo chemical cleaning with a minimum of operator intervention.

BWRO Membrane System

First pass permeate from SWRO treatment is further polished using a second pass BWRO system (mainly for required boron removal). SWRO permeate water is pumped using BWRO HP pumps through another set of reverse osmosis membranes to further remove dissolved solids.Each BWRO train consists of dedicated BWRO HP pump, RO pressure vessels, RO modules, and necessary valves and instruments. Each train is equipped with 14 nos. of pressure vessels, each containing 7 nos, of RO elements, having a total of 98 nos. of RO modules per train. BWRO train operation is fully automatic and each train runs independently to produce polished desalinated water. The CIP system used for SWRO cleaning is also used for the BWRO trains.

Provision by owner

• Seawater intake, outfall and waste discharge system

• Civil and structural works

• Site works (site logistics site installation, interface connection and utilities)

• Utilities

• Commissioning works support

• Permits and Approvals

• Logistics

Intermediate Storage Tanks (by Customer)

• The following is only a guideline, and the tanks to be constructed by Customer will be

based on the storage and retention volume needed.

• The size of the respective intermediate storage tanks are indicated for reference only. The

Customer can select the tank size according to the layout and space available.

For more information please contact the undersigned

Packaging & Delivery

Packaging Details: fully containerized RO Plant

Delivery Detail: ready for delivery after agreement and payment